PEI Blog

Alyse Falconer, PE, LEED AP BD+C, Joins PEI as Associate Principal

On 07, Sep 2017 | In PEI Blog | By Larry

Point Energy Innovations (PEI), a leader in sustainable design and engineering for the built environment, announces the appointment of Alyse Falconer, PE, LEED AP BD+C, as Associate Principal. The announcement is made by Peter Rumsey, PE, FASHRAE, CEM, Founder and President of Point Energy Innovations.

“We are delighted to have Alyse join our team of highly specialized individuals,” commented Rumsey. “She’s an up-and-coming leader in the design and specifications of high-performance, sustainable buildings,” he added. Prior to joining PEI, Falconer was a Senior Mechanical Engineer at Interface Engineering in San Francisco, while previously with Buro Happold in New York.

Originally from Pittsburgh, PA, Falconer is a Golden Gate Chapter Board Member of the American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and is a member of the Urban Land Institute (ULI). She received her Bachelor of Architectural Engineering from the 5-year program at Penn State University, University Park. A resident of San Francisco, Falconer says of her professional work, “I am motivated every day to improve people’s lives through the built environment and to be a role model, so that young women can have someone to look up to and say, ‘I can go into engineering, too.’ I strongly believe in giving back through volunteer work.”

PEI works with developers, owners, architects and contractors as a strategic front-end mechanical, engineering and plumbing (MEP) consultant. Founded by Peter Rumsey in 2013, the small firm provides strategic design services for building HVAC, lighting, electrical and plumbing systems. PEI specializes in highly cost effective net-zero energy and sustainable buildings. Tech clients include Google, Workday and Infosys. Higher education clients include the University of California, Georgia Tech, and MIT. Development clients include Landbank Development in Sunnyvale, Pacific Union Development in San Francisco, and Sharp Development in San Jose.

Efficient Buildings in India: Opportunity Lost or the Opportunity of a Generation?

On 05, Sep 2017 | In PEI Blog | By Peter

By Peter Rumsey

On a recent trip to India, the scale of construction and vitality of the country again struck me. India is undergoing a tremendous building boom; everywhere one goes the sky is full of construction cranes. To give a sense of the magnitude, a full 20% of the India’s GDP is construction, employing some 35 million people. In all this chaos is hope for the changing prospects for millions of people who are getting their family’s first shot at the middle class, modest as the Indian version is. But with this opportunity come several pitfalls. One of the consequences of the rapid growth is air pollution, now plaguing the country’s largest cities. Most large cities suffer rolling blackouts for a good part of the year; there simply isn’t enough power. The imperative to build more efficient buildings has never been greater.

India’s extreme pollution is compounded by ever-increasing energy demands and the continued use of coal-fired power plants.

Point Energy Innovations (PEI) is working with developers to design buildings that are significantly more efficient and more resilient. Efficiency allows for smaller cooling systems, transformers and generators. We are providing strategic-level design services to a massive new community representing over 10 million sq. ft. in apartment buildings, office buildings, hospital, hotel, schools, a shopping mall, greenways and a park. Two other developer clients are each building one million sq. ft. office buildings.

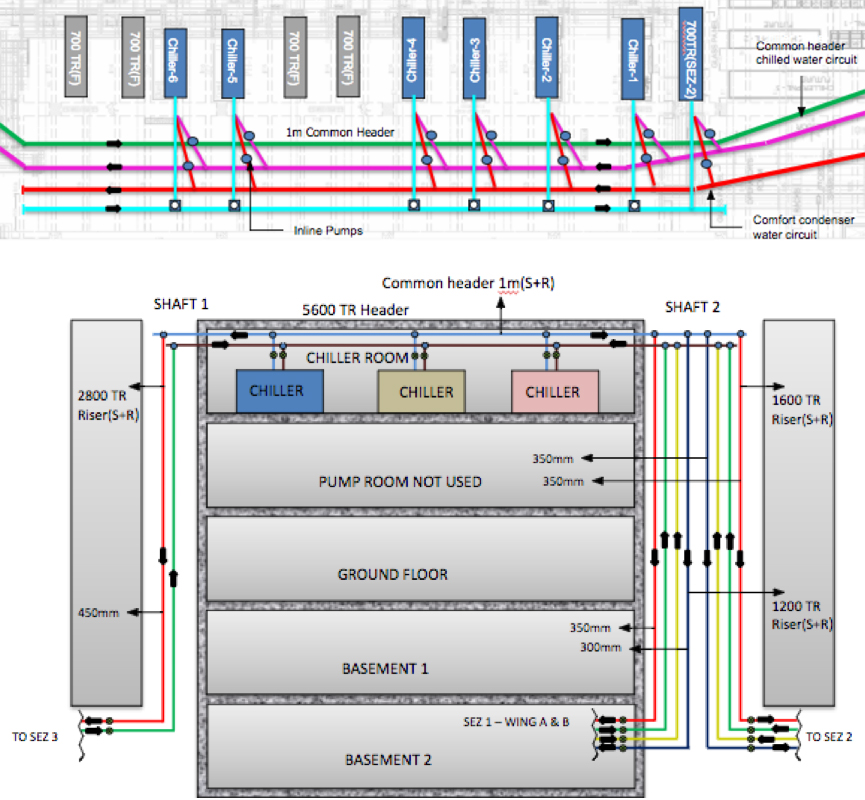

One of the two large-scale developments in India for which PEI is providing strategic design services, including specification of cooling, transformers and generators which require less power.

Many of the developers in India are new to the industry. In May I gave a talk to a young developers association; the members were all very sharp and mostly educated in top universities in the US or Europe. I was chatting with one of the attendees about his new residential project. When I asked the size, he casually responded 4.5 million sq. ft. Quite a surprise for me, but not uncommon in India. The need for housing and office space is immense. In contrast with the United States, a 4.5 million sq. ft. project is a once-in-a-lifetime opportunity and only for seasoned veterans.

Demand for commercial office space is driven by a mix of local and foreign corporations seeking to take advantage of the huge supply of software engineers and information workers in the country. When a company needs office space, they hire agents, usually international advisory firms, to represent them in their search. Typically, the agent issues an RFP to developers that include specific assurances for cooling systems and generator capacity, etc. It’s common to see clients requiring 8-10 watts per sq. ft. of generator capacity and 250 sq. ft. per ton of cooling system equipment sizing. These companies will go so far as to say if you don’t have this, then our client is not interested in leasing space your building.

With our projects, we have demonstrated an alternative, one whereby developers can bring their construction costs down by making more efficient buildings. We help clients select better windows, more efficient curtain walls, LED lighting, improved insulation and energy-efficient chilled water plants for HVAC systems. More efficient buildings require smaller chilled water plants, transformers and generators and are thus cheaper to build. These buildings only require 4-5 Watts per sf of generator capacity 400-500 sq. ft. per ton of cooling system capacity. This is half of what tenants and their agents require.

A highly-efficient chilled water plant in India, as specified by PEI for one of the large mixed-use developments under construction.

Herein lies the dilemma. The more affordable building is the more efficient building. The more efficient building should provide lower rents to tenants and help deal with India’s struggling power sector and air pollution. But developers are reluctant to go against the standards that agents for those tenants have set.

A new standard is needed. We have encouraged our developers to guarantee temperatures for cooling systems and uptime on electrical systems instead of actual sizes. And we have initiated conversations with two of the international real estate consulting firms with a broad reach in India. It will take some time to change this paradigm. Unfortunately, the paradigm is one which was developed in the US and Europe. All too often, in my work in the US, I see tenant agreements with power requirements based on Watts per sq. ft., and cooling based on sq. ft. per ton.

PEI’s design of advanced chiller plants results in lower power requirements.

Every building built in India during this construction boom that uses the current metrics thereby missing the benefits of efficiency, is a lost opportunity. The building sector needs to catch up to other sectors such as transport and renewables generation. India plans to ban all internal combustion cars within the next 13 years. Speaking at the World Economic Forum, Piyush Goyal, India’s Energy Minister, says, “Not a single petrol or diesel car should be sold in the country by 2030.” The government is actively encouraging photovoltaic-generated (PV) electricity. And utilities are not resisting, unlike in some parts of the U.S. PV systems on commercial buildings are being installed widely. Recent central utility scale PV bids have been at less than $0.02/kWh. This represents some of the lowest pricing in the world.

One thing Silicon Valley has taught me is: when there is gross market inefficiency, it’s only a matter of time before a new business model emerges. New leasing models and requirements based on delivering services – not size – need to become the norm. More efficient and lower cost buildings are a win-win for both developers and tenants alike and cannot come soon enough to the booming construction industry in India.

What Should We Do about PV Waste?

On 12, Dec 2016 | In PEI Blog | By Molly

By Rubi Rodriguez Mendoza

(Photo: Dennis Schroeder/NREL)

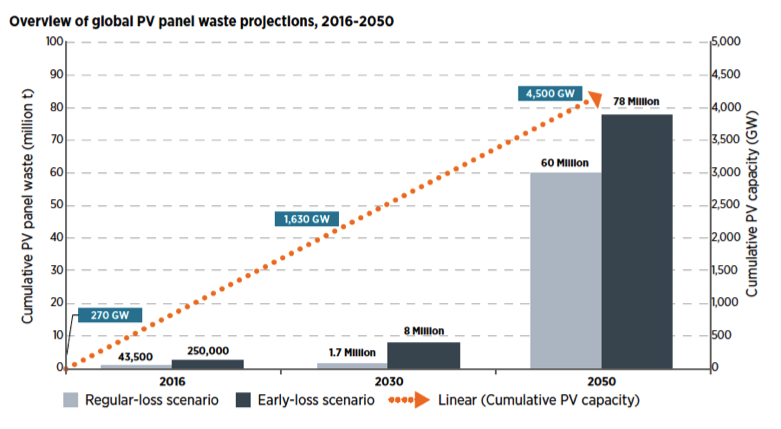

Solar has grown at unprecedented rates since the early 2000s. Global PV installed capacity reached 222 GW at the end of 2015, yet it is still expected to rise to 4,500 GW by 2050. In the U.S., the current PV installed capacity is 27 GW and it is forecast to reach 600GW by 2050, according to the International Renewable Energy Agency. This is great for consumers and for the environment. However, everything we manufacture does generate waste, even PV. PV panels are very durable, with few moving parts, so they last a long time, 30 years or more, according to SolarCity. But the growth in the PV industry will increase PV waste in the next 20-30 years in the world. The good news is that most PV components can be recycled. Recycling of PV panels is just taking off in the US, but Europe has set standards and best practices the US can also adopt.

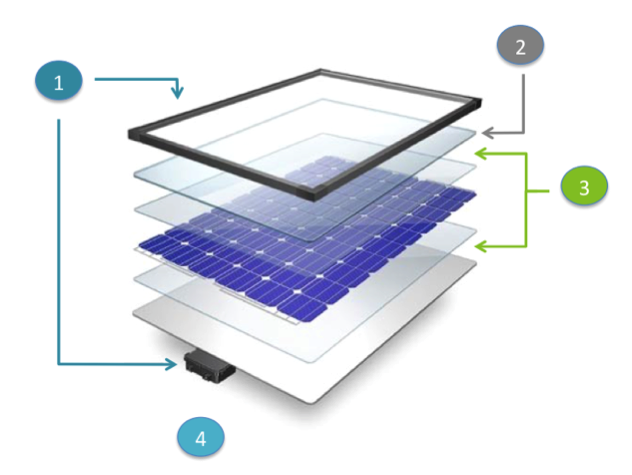

How Components are Recycled

Photovoltaic panels consist of layers of glass, encapsulant EVA (ethylene vinyl acetate), silicon wafers and metallic conductors connected to a junction box. These components are mechanically and chemically separated during the recycling process and returned to manufacturers for incorporation into new products. You can read a detailed description of the recycling process here.

Europe & US Regulations

The extent to which the PV panels are recycled is closely tied with regulations that foster environmental practices in the solar industry. For instance PV Cycle, a European non-profit organization founded in 2007, works closely with governments and companies in the private sector to establish PV waste management strategies and legal compliance for companies and waste producers. PV Cycle partners with industries and governments to reduce the environmental impact of end-life PV panels and to require recycling to be the responsibility of producers. Currently, it is collaborating with manufacturing companies to adopt a design-for-recycling mindset so that PVs are easier and cheaper to recycle.

By contrast, the U.S. is just starting to develop policies and regulations for PV recycling. In October of 2015, California updated its Photovoltaic Panel Collection and Recycling Act of 2014 to require that “a PV panel producer shall establish and operate a take-back program for the collection, transportation, recovery, and environmentally sound recycling of end-of-life PV panels.” There may come a day when recycling PV panels will be enough of an economic opportunity, as new infrastructure for waste management emerges, that it won’t be so dependent on regulations, according to a report by IRENA.

Recycling Opportunities for the Future

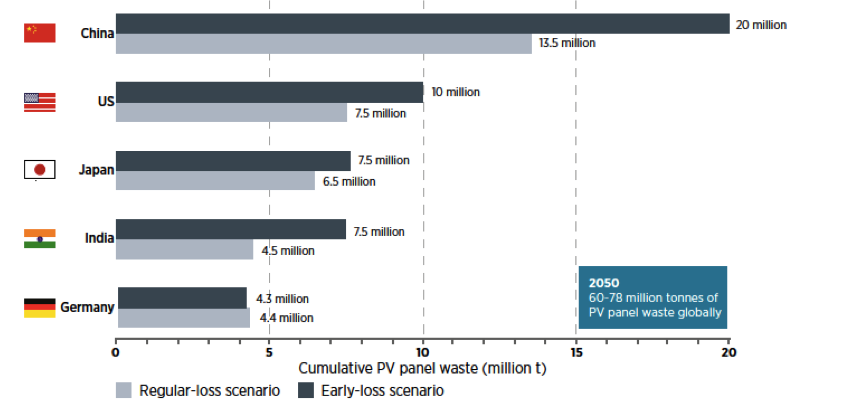

Given that cumulative end-of-life PV waste volume in the U.S. is expected to grow from 6,500 tons at the end of 2016 to 7.5 to 10 million tons by 2050, a big opportunity for growth of the PV recycling market exists. For instance, First Solar, one of the few U.S.-based companies to do PV recycling, could likely benefit from this trend by creating more recycling sites in the country or increasing the recycling capacity of its sites.

Cumulative waste volumes of top five countries for end-of-life PV panels in 2050 (IRENA)

(click to enlarge)

Countries that foresee growth in their PV markets need to develop policies and markets to address the environmental impact of future PV waste volume. Programs like PV Cycle and regulations such as the California Recycling Act are a good foundation to make necessary improvements. PV waste management will absolutely be a challenge in the coming years. Therefore we need to find synergy between the different parties involved in the PV market, including science, technology, business and policy, in order to reduce the negative environmental impact of end-of-life PV panels.